The requirements and applications of different grades of clean room are different. The following are some common clean room grades and their requirements and application examples:

1. Class 10 clean room

Requirements: There should be no more than 10 particles with a diameter greater than 0.5 μm per cubic foot in the air, and the indoor pressure should be positive relative to the surrounding environment.

Application: Suitable for high-precision production and experimental research in the fields of semiconductor production, microprocessor manufacturing, optoelectronics and pharmaceutical production.

2. Class 100 clean room

Requirements: There should be no more than 100 particles with a diameter greater than 0.5 μm per cubic foot in the air, and the indoor pressure should be positive relative to the surrounding environment.

Application: It is suitable for production and experimental research in the fields of precision instruments, electronic components, and biological products.

3. Class 1000 clean room

Requirements: The air should not exceed 1,000 particles with a diameter larger than 0.5 μm per cubic foot, and the indoor pressure should be slightly positive or negative relative to the surrounding environment.

Application: Suitable for production and experimental research in food processing, cosmetics production, pharmaceutical packaging and other fields.

4. Class 10000 clean room

Requirements: The air should not exceed 10,000 particles with a diameter larger than 0.5 μm per cubic foot, and the indoor pressure should be slightly positive or negative relative to the surrounding environment.

Application: It is suitable for the production environment requiring high cleanliness such as pharmaceutical industry, chemical factory and textile factory.

It is necessary to select the corresponding clean room level according to the specific industry and requirements to achieve the best production effect and product quality requirements.

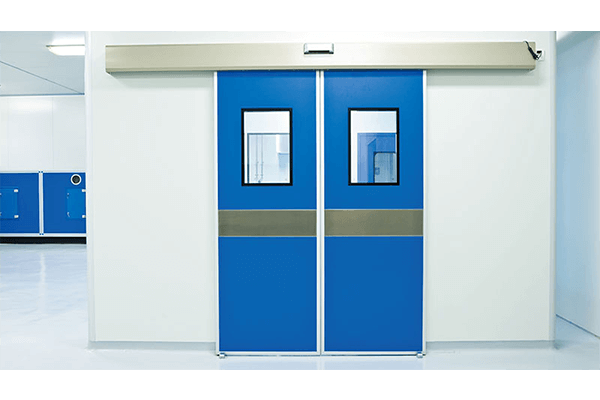

Jiangsu Rongshida Purification Technology Co., Ltd offer Cleanroom Door for hospitals

中文简体

中文简体 English

English

online service

online service 86-400-000-5136

86-400-000-5136

400-000-5136

400-000-5136