The insulation performance of handmade sandwich panels depends on several factors, primarily the choice of core material and the facing materials used. Insulation performance refers to a material's ability to resist the transfer of heat, sound, or both. Here's how different core materials and facing materials can affect the insulation performance of handmade sandwich panels:

1. Core Material:

Foam Core: Foam cores, such as expanded polystyrene (EPS) or polyurethane foam, are known for their excellent thermal insulation properties. They provide effective insulation against heat transfer, making them suitable for applications where temperature control is essential. They also offer some sound insulation.

Honeycomb Core: Honeycomb cores have good strength-to-weight ratios but offer limited thermal insulation. They are often used in applications where structural strength is more critical than thermal or sound insulation.

Plywood Core: Plywood cores provide structural strength but have limited inherent insulation properties. Additional insulation materials may be added between the plywood layers to improve thermal performance.

Balsa Wood Core: Balsa wood cores offer natural insulation properties, including both thermal and sound insulation. They are lightweight and effective at reducing heat transfer.

2. Facing Material:

Fiberglass Facing: Fiberglass facings are often used for their resistance to moisture and corrosion. They offer some thermal insulation but may require additional insulation materials between layers for optimal performance.

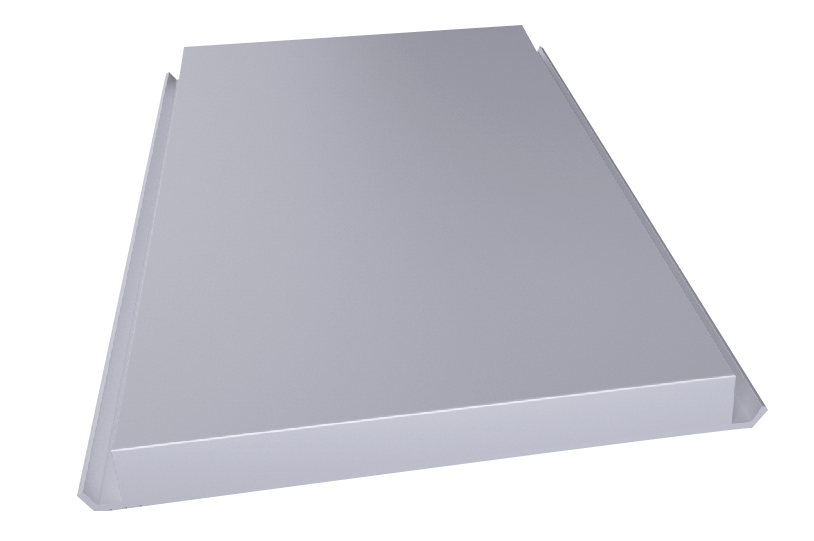

Aluminum Facing: Aluminum facings are lightweight and durable but have limited thermal insulation properties. They are commonly used in applications where strength and corrosion resistance are more critical.

Steel Facing: Steel facings are strong and provide excellent structural support but have minimal thermal insulation properties. They are primarily used for their durability.

Plastic or PVC Facing: Plastic or PVC facings offer resistance to moisture but typically provide limited thermal insulation. They may be suitable for indoor applications.

Composite Facing: Composite facings may combine materials like fiberglass and resin to offer a balance of strength and insulation. The insulation performance depends on the specific composite composition.

3. Additional Insulation: For improved insulation performance, especially for thermal or sound insulation, additional insulation materials, such as fiberglass batts or foam boards, can be added within the sandwich panel construction. This enhances the overall insulation properties of the handmade sandwich panels.

中文简体

中文简体 English

English

online service

online service 86-400-000-5136

86-400-000-5136

400-000-5136

400-000-5136